Vinyl chloride resin saving resources and energy

The main raw materials of vinyl chloride are chlorine, which is obtained by decomposing inexhaustible natural salt on the planet, and ethylene, which is obtained from oil.

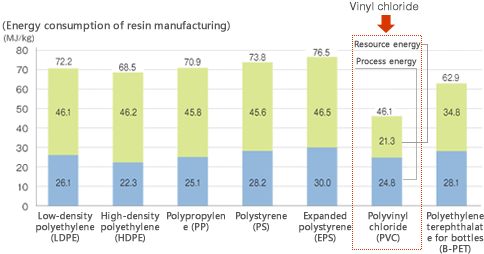

Vinyl chloride is resource-saving compared with most plastic materials, which use oil as the 100% raw material. The amount of energy in the production process is much smaller than the other plastic materials, so it is also an energy-saving material.

Comparing the LCIs (life cycle inventory) of representative general-purpose resins, the process energy from the mining of oil to manufacturing of resins is 22.3 to 30.0 MJ/kg and there is no significant difference among resins. However, as for resource energy, while the energy of the resins which mainly contain carbon hydride from oil is 45.6 to 46.5 MJ/kg, that of vinyl resin, in which chlorine accounts for over half of its weight, is 21.3 MJ/kg, half or smaller than that of the other resins. This means that its loads are small.

The total energy loads of the process and resources of vinyl chloride resin (46.1 MJ/kg) are 64% of those of low-density polyethylene (LDPE)(72.2 MJ/kg), which is often used for packaging materials, so vinyl chloride resin is a good material with the smallest energy loads.

Source: Vinyl Environmental Council

LCI data of general-purpose resin manufacturing

Source: (One company) Plastic Waste Management Institute "Survey Report for LCI Data of Petrochemical Products" (Mar, 2009)

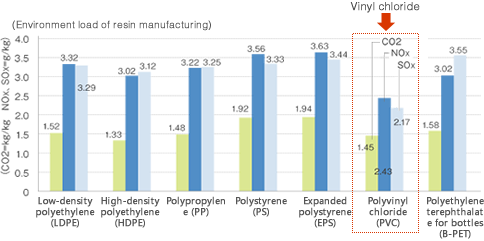

Generating less emissions of substances of concern

The substances of concern generated during the manufacturing process of products include CO2 (carbon dioxide), SOx (sulfur oxide), and NOx (nitrogen oxide).

In terms of substances of concern, the amounts of CO2, NOx, and SOx are 1.45kg/kg, 2.43g/kg, and 2.17g/kg, respectively. The amount of CO2 is smaller than most of the other general-purpose resins and especially those of NOx and SOx are the smallest among general-purpose resins. Therefore, it is reappraised as a good material from the viewpoint of substances of concern as well.

Source: Vinyl Environmental Council

LCI data of general-purpose resin manufacturing

Source: (One company) Plastic Waste Management Institute "Survey Report for LCI Data of Petrochemical Products" (Mar, 2009)

High recyclability

A nationwide recycling network has been established for vinyl chloride resin products such as vinyl chloride pipes and agricultural vinyl films. With the material cycle rate being higher than that of the other plastic materials, vinyl chloride floor materials are manufactured using recycled materials.

The cycle to collect and recycle chlorine is also growing and products whose materials cannot be recycled due to deterioration or contamination can also be recycled through chemical changes.

Safety of vinyl chloride appraised all over the world

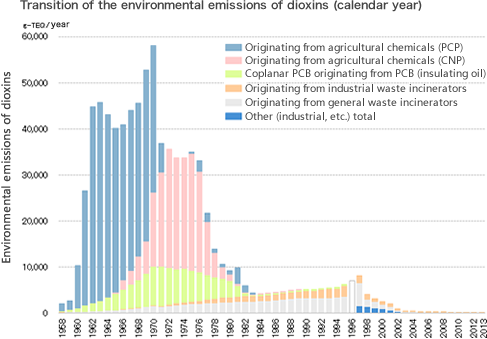

The problem of dioxin emissions from vinyl chloride has long been misunderstood.

It has been found out that the generation of dioxin, which is mainly caused by agricultural chemicals and insulation oil, can be eliminated almost entirely by controlling the incineration method, and the target set in the "Act on Special Measures against Dioxins" has been also achieved steadily.

As for carcinogenicity, vinyl chloride resin (PVC) is assessed as "not classified as carcinogenic," which is equivalent to tap water, by the International Agency for Research on Cancer.

As of now, various misunderstandings about vinyl chloride have been cleared up and its safety is appraised all over the world.

Source: Vinyl Environmental Council

*Data of 1958 to 1995 is based on trial calculation by Professor Shigeki Masunaga of Yokohama National University

*There is no data of 1996 so 1/2 of the total emissions of 1995 and 1997 are adopted

*Data of 1997 and later is created from data of the Ministry of the Environment

Vinyl chloride floor materials certified as eco products by the government

The judgment standard to identify vinyl floor materials as products conforming to the provisions of Act on Promoting Green Purchasing is "The total weight of recycled vinyl resin materials used exceeds 15% of the total weight of the product." About 80% of the floor material products of Lonseal conform to the designated procurement items under the Act on Promoting Green Purchasing. They are eco products certified by the government.

They are also certified for the Eco Mark, which is an environment label attached to products judged to have little environment load throughout the life cycle from "production" to "disposal" and help environment conservation by the same standard.

In addition, recycling significantly reduces the manufacturing energy, contributing as well to the reduction in CO2 emissions in the process to produce floor materials.

*Act on Promoting Green Purchasing indicates "Act concerning the Promotion of Procurement of Eco-Friendly Goods and Services by the State and Other Entities"

(Act No. 100 of May 31, 2000).

![]()

- About the conformity logo mark

- I.F.A (Interior Floor Industrial Association) established a common logo mark which can be displayed in corporate catalogs and sample books to identify conforming products.

Material recycling business of remainders and excess materials

I.F.A (Interior Floor Industrial Association), to which Lonseal belongs, runs material recycling business of remainders and excess materials generated during construction due to "wide-area recycling designation" by the Ministry of the Environment. Among vinyl floor materials manufactured or sold, "vinyl floor sheet and vinyl baseboard," "cushion floor," and "homogeneous tile" are separated and recycled for vinyl floor materials. Floor materials manufactured by manufacturers belonging to I.F.A can be recycled even if mixed.